Pneumatic actuators for generating linear or rotary motion

A wide range of pneumatic actuators is available. These devices can be used to generate different types of mechanical motion, by converting energy of compressed air or gas. Various types of pneumatic actuator types are available, to generate both linear and rotary motion. They are mainly used to remotely control valves in a system. We stock renowned brands such as Bosch, Festo, and Rexroth. All actuators, both brand new and used, are available for direct shipment.

Pneumatic actuators

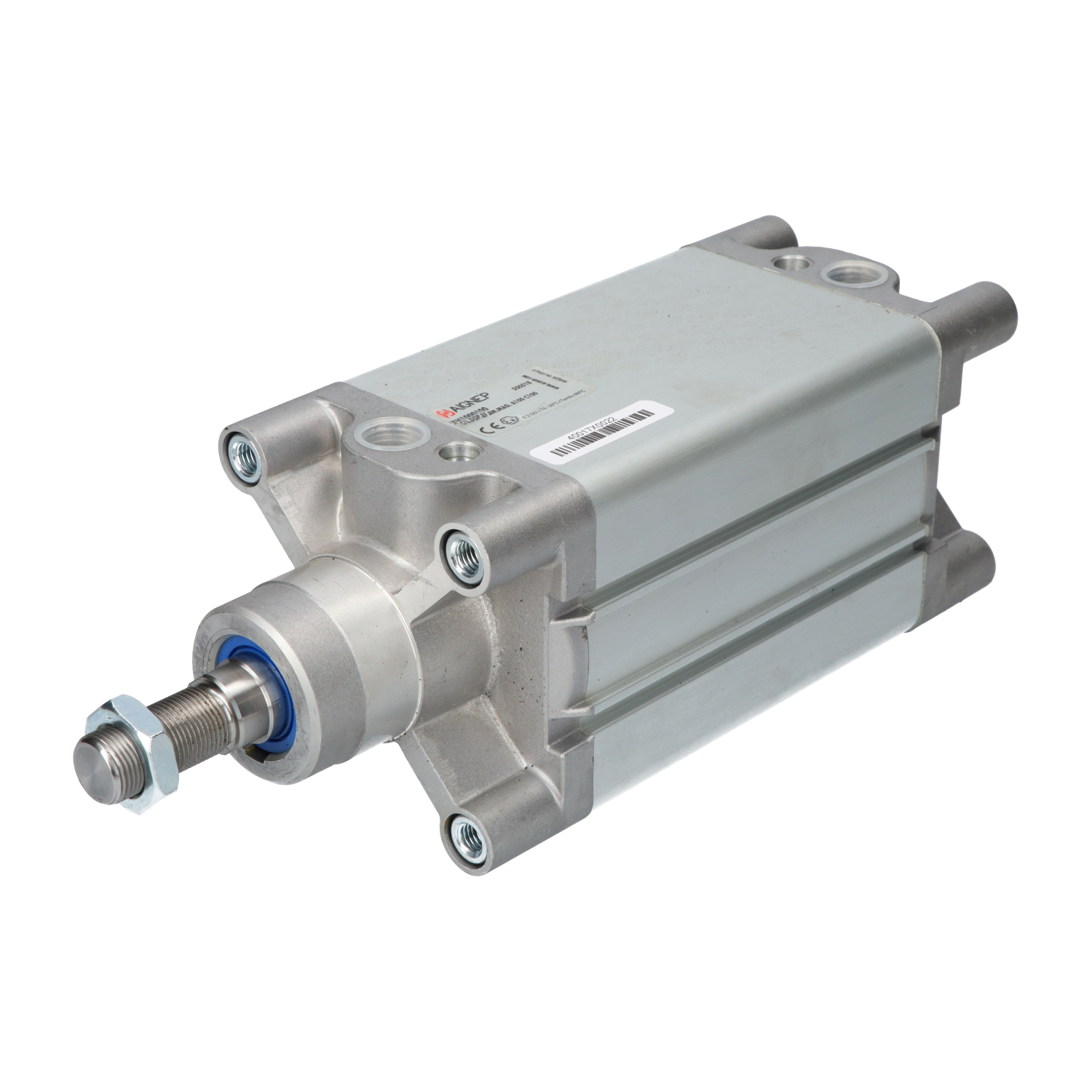

Pneumatic piston rod cylinders

A subdivision can be made, based on the different technical operating principles. Piston style pneumatic actuators feature a piston, placed in a cylinder. This assembly is used to produce a linear motion. When more or less force is exerted on one side of this piston, movement is generated. In the case of double-acting piston style pneumatic actuators, air pressure is applied on both sides of the piston via two separate ports. Single-acting piston style pneumatic actuators employ a spring on one side, while pressure or compressed air enters the other side through a port.

Rodless cylinders

Rodless cylinders are sometimes referred to as rodless actuators or rodless slides. Conventional pneumatic cylinders employ a rod for pushing and pulling loads from the piston. Rodless cylinders, on the other hand, move a load alongside the piston and operate at much higher speeds than conventional cylinders. Objects can be transported over larger distances in less time. This type of cylinder can conduct and support a load over the complete cylinder stroke length. There is no risk of rod bucking issues while handling high loads or long strokes.

Pneumatic rotary rack and pinion actuators

Rotary actuators spin and provide rotational motion, instead of moving in a linear fashion. Several types are available. Rack-and-pinion pneumatic actuators, also known as limited rotation cylinders, boast a relatively high amount of torque in a continuous fashion. A rack and pinion setup converts linear piston force into rotational torque. These actuators are mostly employed in combination with quarter-turn valves for automation purposes involving restricted rotation. Both single rack and dual rack configurations exist.

Pneumatic rotary scotch yoke actuators

Another type is the scotch yoke actuator, which generates even more torque. The peaks occur during the beginning and end of the movement. They generally comprise a crank and piston configuration within a hollow cylinder. Just like rack and pinion actuators, scotch yoke actuators are often combined with ninety-degree rotation valves, such as ball valves and butterfly valves. These devices are very suitable for use with variable torque valves.

Pneumatic rotary vane actuator

A third type is the rotary vane actuator. It has a compact, self-retaining design. Two air chambers are formed in an enclosure by the presence of a vane, dividing them. Both opposing chambers are pressurized and vented, resulting in a pressure differential, which provides torque to the shaft. Throughout the full shaft rotation, the torque output of the rotary vane actuator remains steady.

Guided cylinder

The purpose of a pneumatic cylinder with a guided piston rod is to perform a controlled rotation during the push-in and pull-out stages. Different types of pneumatic guided cylinders exist. Linear slides and drives with guide rod are among them. A linear slide or mini slide has a small design, while guided cylinders with guide rod are especially sturdy. Other examples include multi-mount cylinders and dual-rod cylinders. We also stock guide units for absorbing lateral stress and averting twisting on standard cylinders.

Benefits of pneumatic actuators

Pneumatic actuators require no ignition or electricity. This ensures a very safe and reliable option in environments where sparking and combustion are too much of a hazard. There is no fire risk, and no liquids (corrosive or otherwise) are involved either. Since they don’t rely on combustion, these actuators are relatively simple devices. They are easy to manufacture and very durable at the same time.

Pneumatic actuator applications

Pneumatic actuators can be used in a wide range of applications and industrial environments. They are employed, for example, in factory automation configurations, ignition chambers in gasoline-powered vehicles, air compressors, packaging and production machinery, and transportation equipment.